Home / Bag Filters / FabriClean

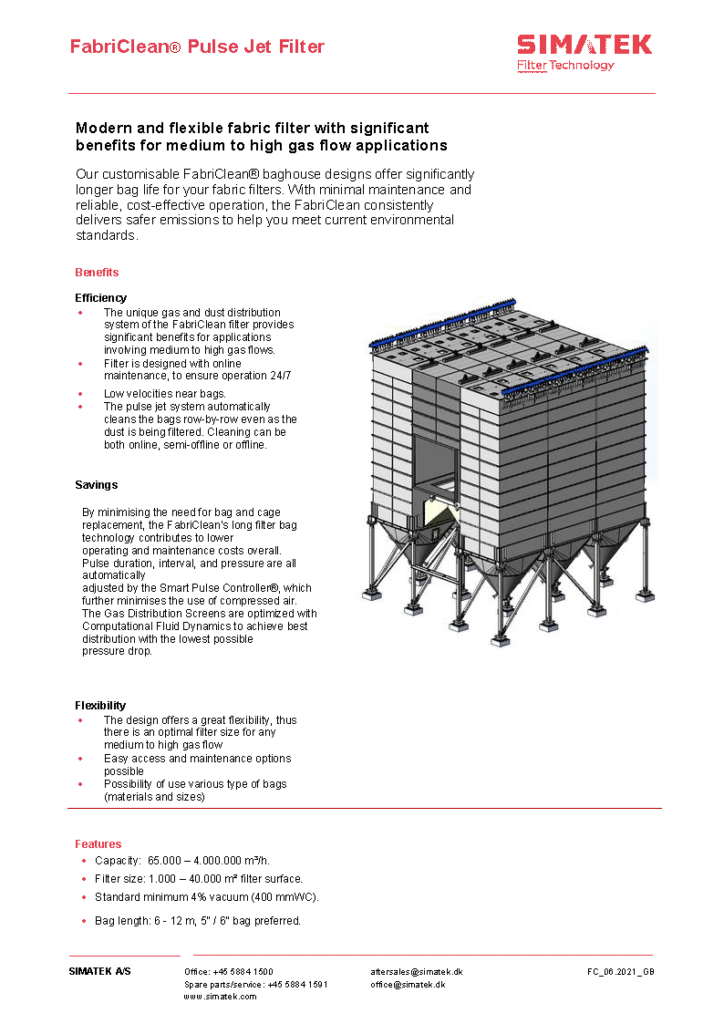

Based on the latest technology the FabriClean is a customisable fabric filter with advantageous benefits for medium to high gas flow applications and with bag length up to 12 m. It is a reliable filter, that offers significantly longer bag life and cost-effective operation. Reduced equipment weight and footprint are also integral to the FabriClean’s design, improving the baghouse’s emission reduction capabilities and minimising its construction time and shipping costs. This all translates to lower CAPEX expenses for your business.

Simple inlet/outlet duct layout

The FabriClean’s clever design makes for simpler installation, maintenance and parts replacements. Inlet and outlet dampers are used to isolate the filter compartments during maintenance periods. If necessary, it is possible to close the outlet damper only to carry out off-line cleaning. For personal safety, a mechanical locking device is supplied to lock the dampers in the closed position.

Unique dust pre-separation and gas distribution systems

The FabriClean’s unique gas distribution system, in combination with a pre-separation of dust optimizes the filter size and reduces the dust load on filter bags resulting in fewer cleaning cycles and minimised compressed air consumption.

When a filter is cleaned on-line, the direction of the gas flow in the compartment is very important. A uniform flow across the distribution screen is ensured by baffle plates and an upward gas flow inside the gas distribution zone. The gas and the remaining dust will then pass the screens and be distributed across the entire bag area, with the dominating gas velocity being downwards. This results in a significant decrease in the amount of pulse air required to clean the filter bags, which reduces your power consumption and extends bag life.

Long filter bag technology and wear minimizing cages

By using filter bags with the highest quality materials available, it has become possible to greatly improve their lifespan. The FabriClean saves you money in the long run by reducing flex fatigue.

Smaller equipment footprint

By minimising the need for bag and cage replacement, the FabriClean’s long filter bag technology contributes to lower operating and maintenance costs overall.

Advanced control system

Our SimControl Advance® ensures a smoot operation adjusting pulse duration, interval and pressure automatically which increases the lifetime of your filter and minimizing the usage of compressed air. This control system incorporates a variety of features that help operate the filter at a minimum energy consumption and ensure identification of any malfunctions, so they can be dealt with quickly and effectively. The control system is designed for both serial and parallel interfaces to the plant control system as well as field components (valves, dampers, instruments). Serial communication is often used, as this system is more cost-effective in terms of both material and time.

For at give dig de bedste oplevelser bruger vi teknologier som cookies til at gemme og/eller få adgang til enhedsoplysninger.