Home / Cement

Cement producers are today met with increasing forces from regulatory pressures and stakeholder expectations regarding health, safety, and environmental performance. This put pressure on the efficiency and operation of the equipment dedusting the various processes and machines on the cement plant.

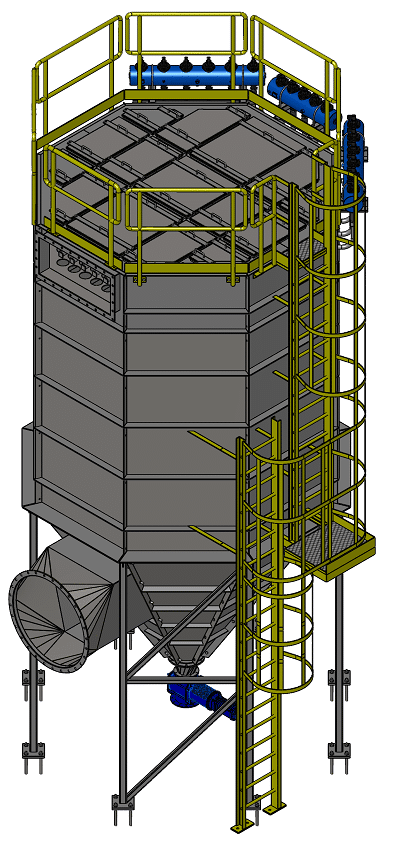

With more than 16,200 fabric filter installations worldwide, our filter technology is well proven meeting today´s requirements. Ranging from 5 m³/h to 4,000,000 m³/h in one single filter unit, they cover all the dedusting requirements on a cement plant.

For further information about our cement dust collector solutions please send your inquiry to office@simatek.com

Learn more about our after sales service and spare parts for Air Pollution Control equipment

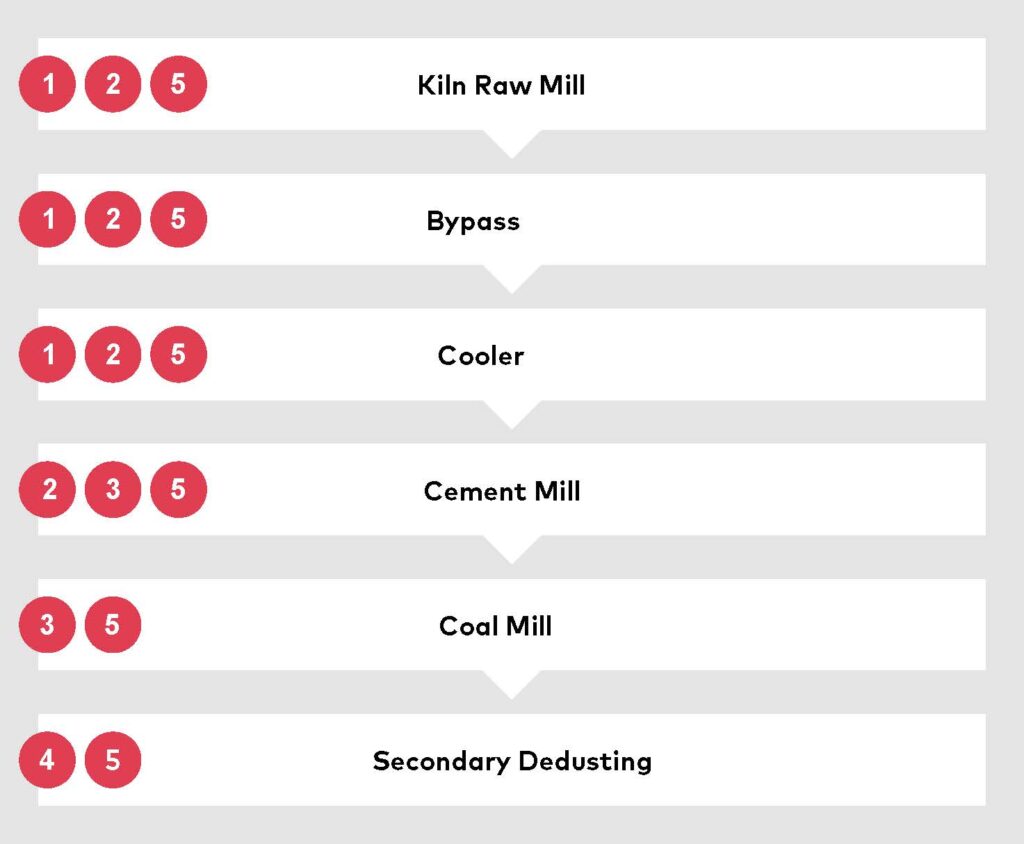

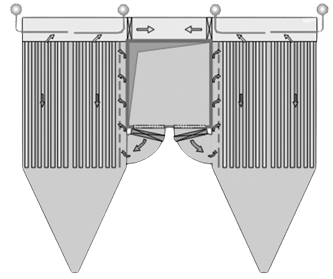

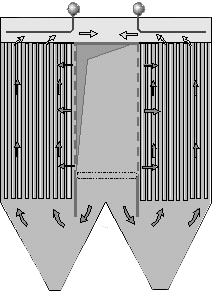

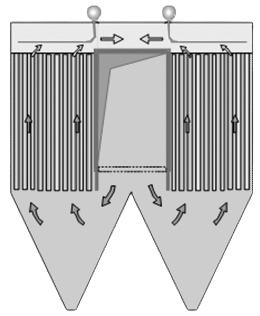

The medium and larger gas volumes are covered by a range of customizable process filters using bags up to 12 m, and able to meet emission guarantees down to only 2,5 mg/Nm³ in selected processes. These filters are designed for kiln/raw mill, alkali bypass, clinker cooler, cement mill and coal mill processes. They are suitable both after air and water cooling.

For the smaller secondary gas volumes Simatek has a number of flexible Nuisance filter (NDC) variations adaptable to transport equipment, silos, mill installations, cement separators, flash dryers and packing plants.

For at give dig de bedste oplevelser bruger vi teknologier som cookies til at gemme og/eller få adgang til enhedsoplysninger.