Home / Biomass

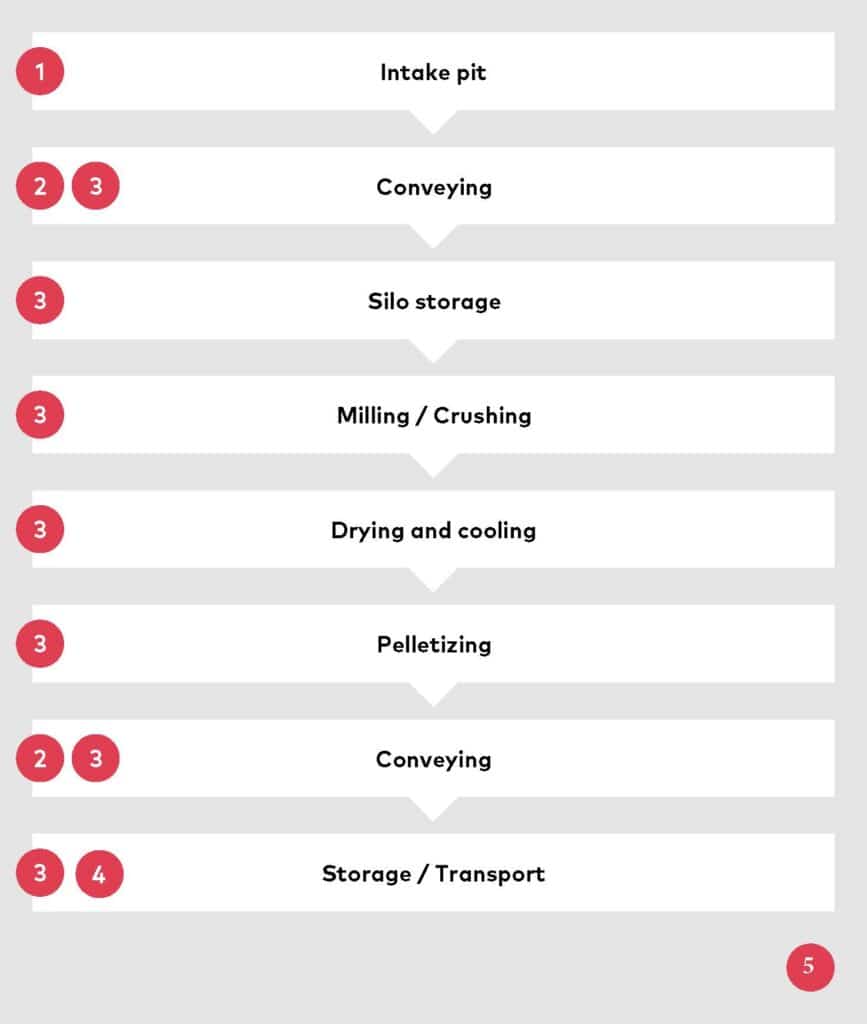

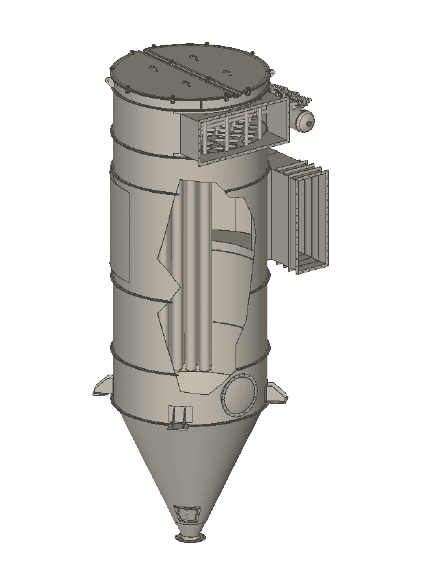

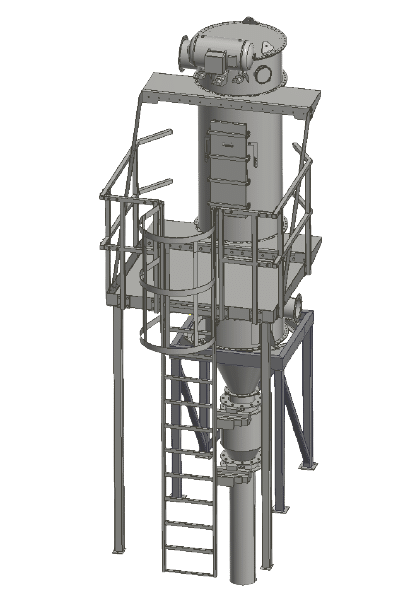

Producing alternative fuels calls for an ever-increasing variety of raw material and state-of-the-art filtration technologies.

The biomass industry needs solutions that can provide continuous and uniform sorting and filtration of fuels like wood pellets, peat and straw.

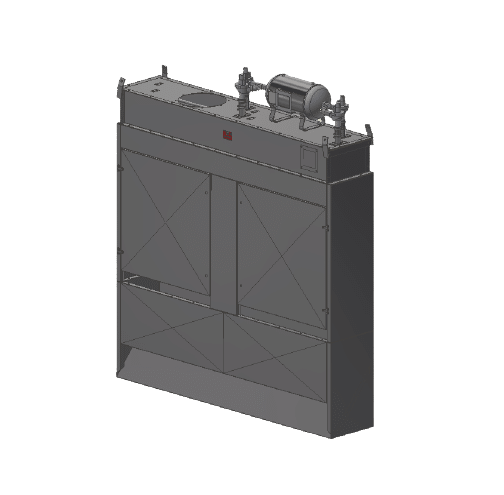

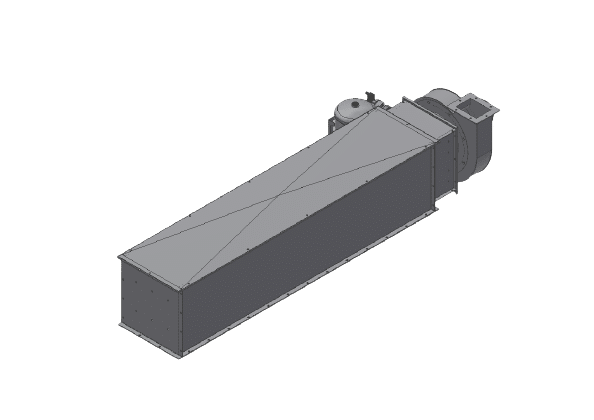

This is where Simatek solutions come in. Our filtration systems meet the required ATEX directives and are designed to be installed in ATEX zone 22. They prevent explosive emissions and dust leakage ensuring high process safety.

Our filtration solutions are based on technology suited for multiple applications.

This helps us offer our customers tailor-made solutions based on their specific needs.

Through our unique technology and specialised expertise, we guarantee optimal process quality, safety, a consistent high-quality product and compliance with regulatory standards.

Our solutions are efficient, environment friendly and offer our customers good value for money.

Our customers benefit from:

For at give dig de bedste oplevelser bruger vi teknologier som cookies til at gemme og/eller få adgang til enhedsoplysninger.