Home / Dairy Powder

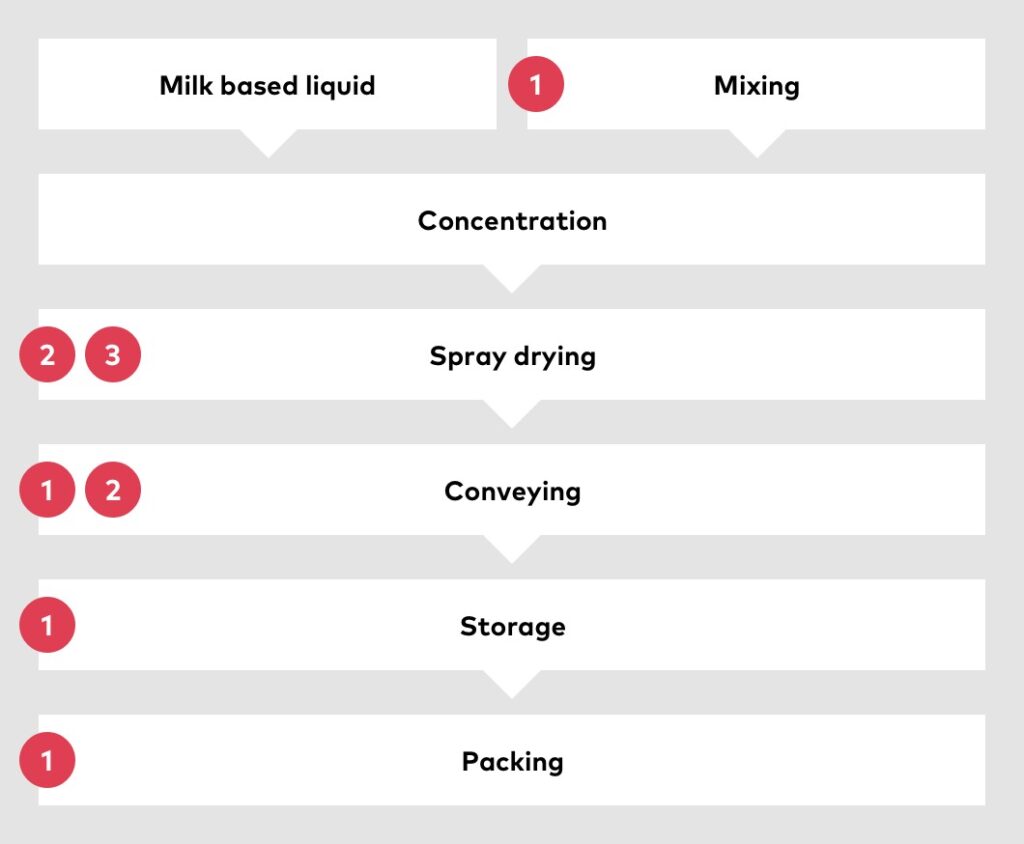

With the rise in global population, the demand for dairy powder is expected to increase. Billions of new low-income consumers will need safe processed food products. The challenge the dairy industry faces is balancing this demand with supply globally.

Shipping dairy products efficiently over long distances is a challenge, whereas dairy powders can be shipped cost effectively. What the dairy industry will need to focus on is continuous adaptation and innovation while keeping prices low at the same time. This calls for cost-efficient investment in equipment, flexible processing equipment, high production efficiency and low downtime – all of which contribute to a low cost of ownership.

With a Simatek bag filter, you not only limit emissions to comply with regulatory requirements, you also increase your bottom line and profits through powder recovery. With typical payback periods of less than three years and with at technical and economic lifetime of more than 20 years, a Simatek bag filter will generate significant increased revenue and a better bottom line year after year.

Powder loss from spray dryers using a conventional cyclone solution is typically in the range of 0.5 to 1.5% of powder production. Our bag filter technology can reduce this to less than 5 mg/Nm³ corresponding to a loss of less than 0.02% of the powder production.

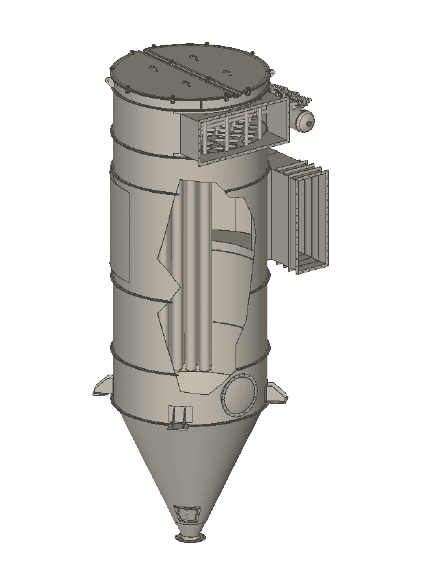

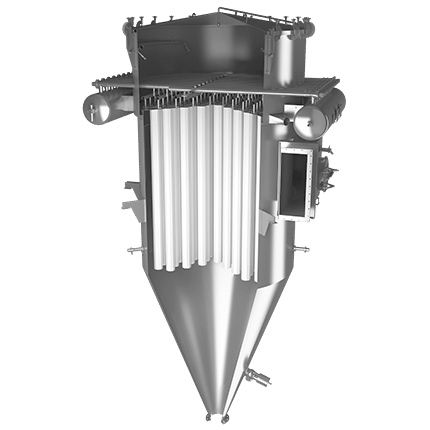

Simatek’s filtration solutions for the dairy powder industry are based on technologies that offer a cost-efficient investment. We do this by providing flexibility in handling a range of dairy powders, a small footprint and low operating costs. This is combined with lower energy consumption through the 3C Pulse Air Distributor – a single bag pulsing system that reduces energy consumption by up to 80%.

The 3C single bag pulsing concept provides far less pulsation in the drying system. Lower pressure drop over the bag filter reduces the energy consumption at the outlet fan by up to 30%.

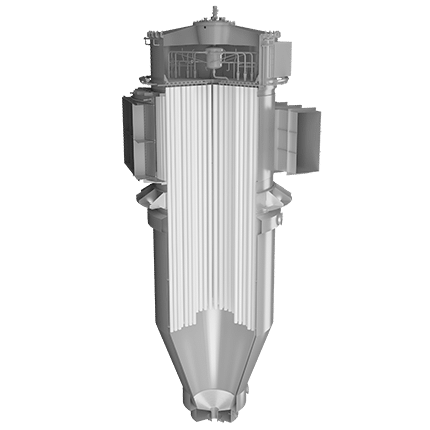

Our SimPact 4T bag filter utilizes conventional high-pressure bag pulsing technology and cleans the filter bags in rows. The SimPact 4T bag filter is available as an alternative to the SimPulse 3C bag filter.

Our bag filters for the dairy powder industry also meet the required hygiene design standards including the European, 3-A and USDA.

For at give dig de bedste oplevelser bruger vi teknologier som cookies til at gemme og/eller få adgang til enhedsoplysninger.