Home / Grain & Feed

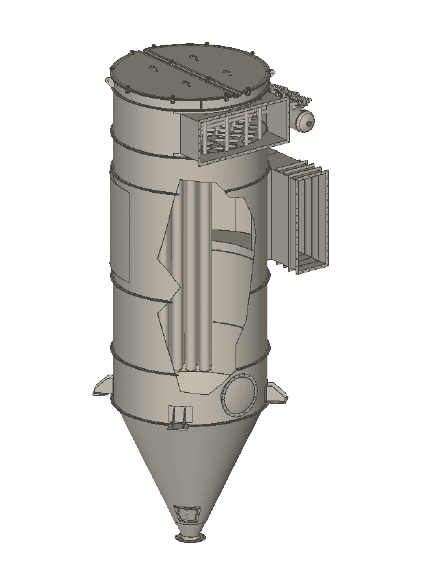

Grain and feed products generate a high volume of dust during production. This presents a safety hazard for employees working in the plants and the equipment used.

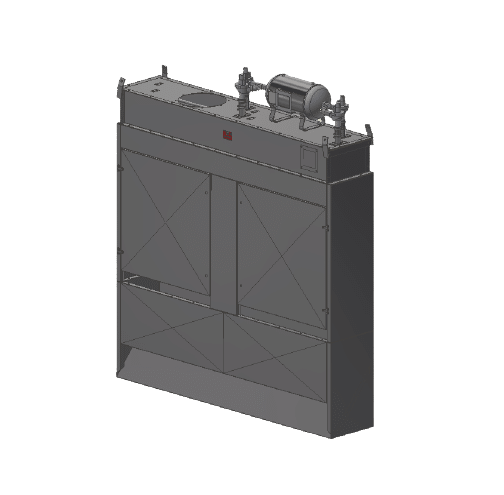

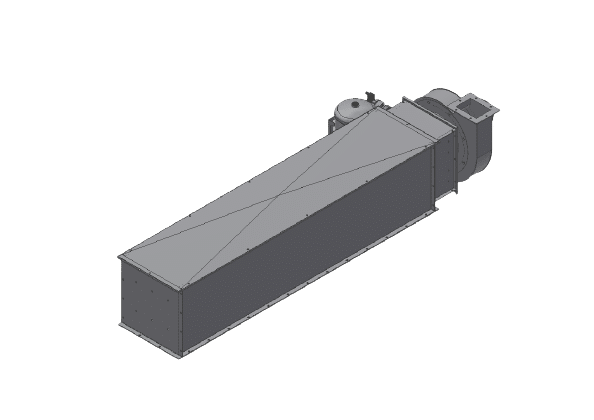

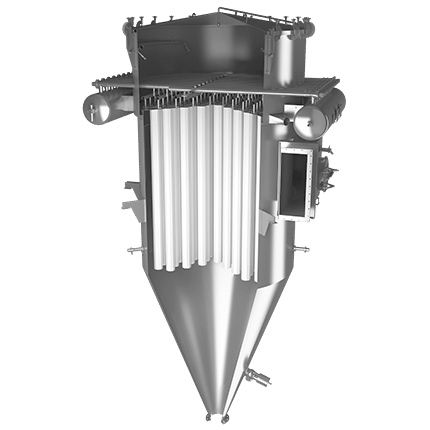

Simatek offers solutions that meet the industry’s needs in terms of health and safety, hygiene, product quality and product recovery – irrespective of the volume of dust generated. Our solutions are designed and manufactured according to the feed hygiene and food guidelines of the EHEDG.

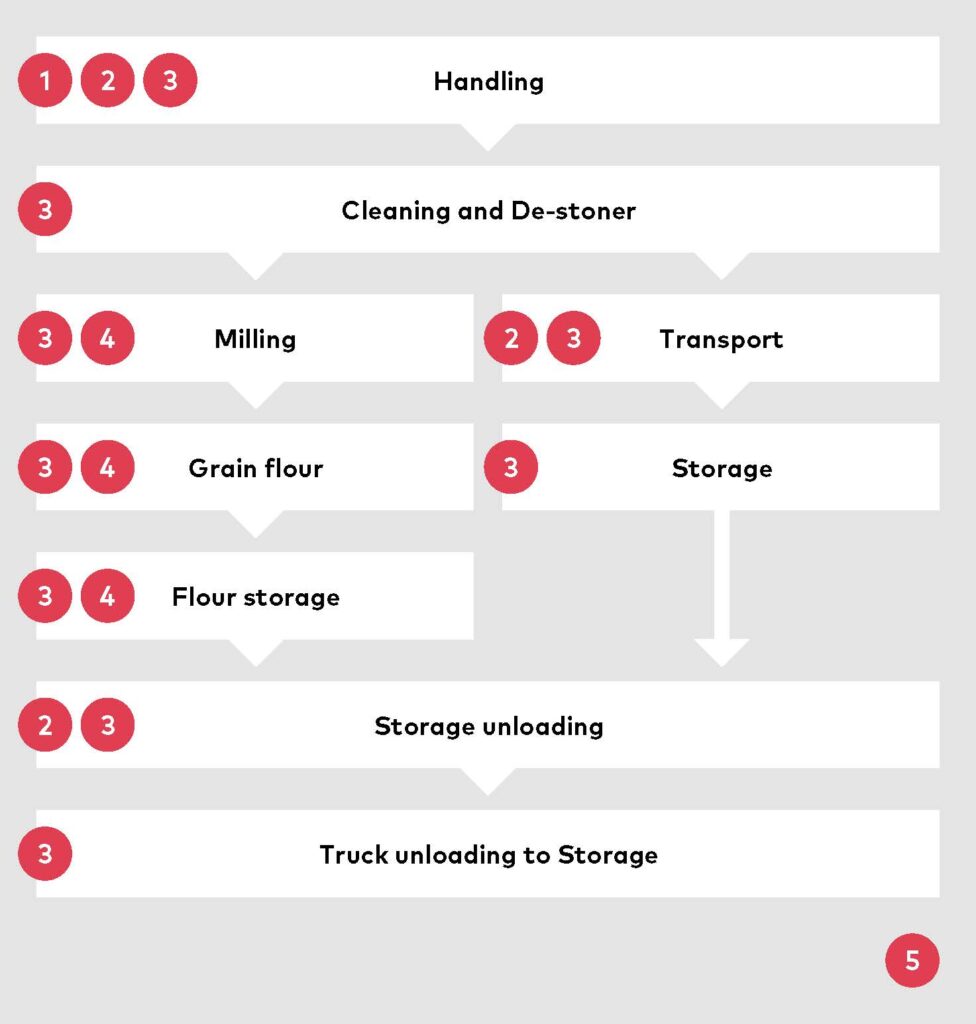

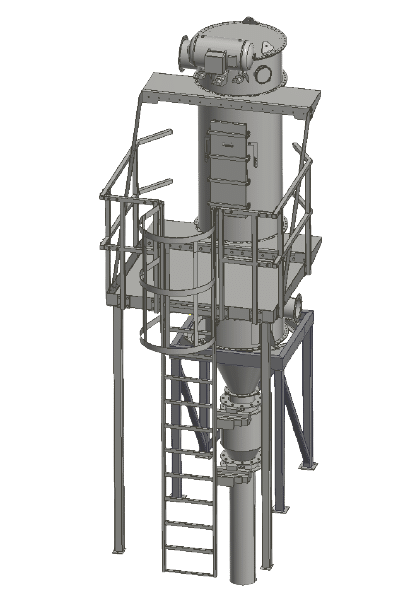

Our solutions are based on a flexible modular design with a wide range of applications.

We deliver efficiency and performance by developing customised solutions for our customers.

In addition to being efficient, our solutions are environment friendly and offer customers good value for money.

Our customers benefit from:

For at give dig de bedste oplevelser bruger vi teknologier som cookies til at gemme og/eller få adgang til enhedsoplysninger.